Aikuma Japanese Dyes

Sukumo indigo (Made in Japan)

Sukumo indigo (Made in Japan)

Couldn't load pickup availability

Amount used

3 times the weight of the fabric

Summary

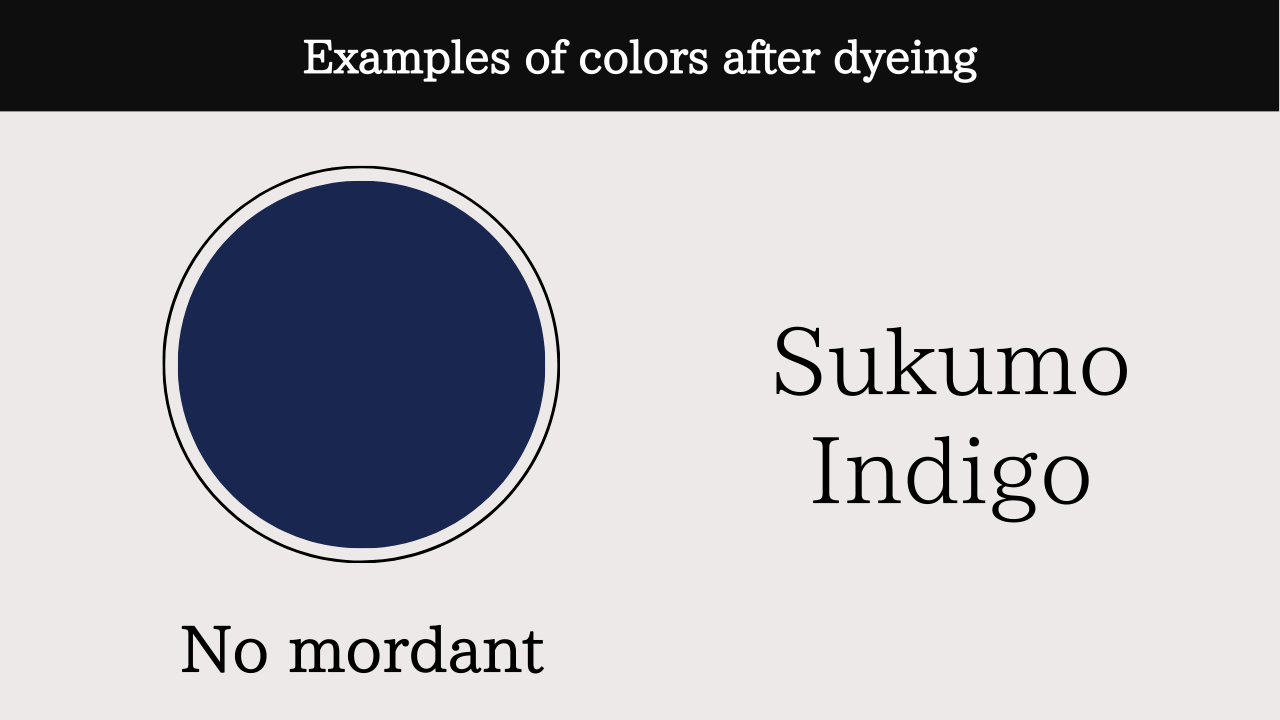

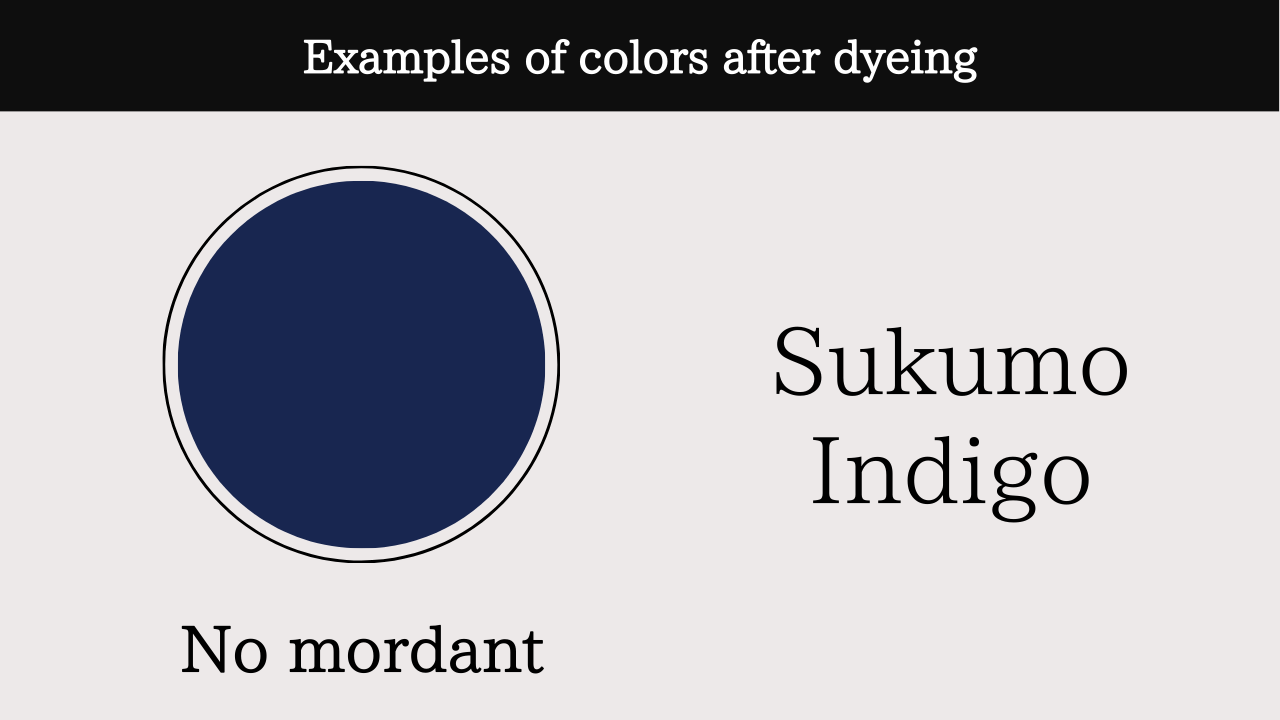

Sukumo indigo is a traditional indigo mainly produced in Tokushima Prefecture. Making the Sukumo indigo process is hard and it takes 3 months normally. After drying and grinding the leaves of indigo, the craftsmen of Sukumo have to remove the stems and water them. In addition, let them ferment the leaves should be mixed well. Specifically, after the indigo leaves are dried and crushed, water is added to the leaves and they undergo a fermentation process.

The number of farmers producing the Sukumo indigo has been decreasing, and the indigo producer we deal with (Mr. Sato) received an award from the Japanese government in 1978 for his outstanding technique. This is a message from Mr. Sato.

Dyeing method

Reduce it with hydro sulfite or other types of alkaline such as Oaktree ash.

Let's try indigo Katazome (Stencil dye) with these beautiful tools.

Key Points

Natural indigo has a tendency not to dye deeply because of chlorine in the water. Therefore, the water which makes indigo liquid is appropriate for the following.

・Pumping (about half a day in sunlight, at least 24 hours indoors)

・Boiling (boil for at least 10 minutes)

The water used for oxidizing or fixing doesn’t need to be them. The amount of water used for oxidation/color fixing during dyeing depends on the weight of the fabric to be dyed. Please prepare 30~40 times the weight of the fabric.